Mettler Toledo pH electrode InPro3100/InPro3100UD Instruções de operação

- Tipo

- Instruções de operação

InPro 3100 (i) pH electrode

52 002 293 C

InPro 3100 (i)

pH Electrode

Instruction Manual

cs Návod k obsluze 2

da Brugsanvisning 6

de Betriebsanleitung 10

en Instruction Manual 14

es Manual de instrucciones 18

fr Instructions d’utilisation 22

Käyttöohje 26

hu Használatiutasítás 30

it Istruzioni per l‘uso 34

ja 38

ko 사용 매뉴얼 42

nl Gebruikershandleiding 46

pl Instrukcjaobsługi 50

pt Manual de instruções 54

ru Инструкцияпоэксплуатации 58

sv Bruksanvisning 62

th 66

zh 70

2 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

1 Úvod .............................................................................. 3

2 Bezpečnostnípokyny ....................................................... 3

3 Popis produktu ................................................................ 3

4 Instalaceauvedenídoprovozu......................................... 4

5 Provoz ............................................................................ 4

5.1 KalibraceelektrodyapřevodníkupH ................................. 4

5.2 Sterilizaceelektrody ......................................................... 4

5.3 TeplotníčidloproInPro3100(analogováverze) ................. 4

6 Údržba ........................................................................... 5

7 Odstraňovánípotíží(dlouháreakčnídoba,

nedostatečnácitlivostatd.) ............................................... 5

8 Likvidace ........................................................................ 5

9 Záruka ............................................................................ 5

Obsah

cs

InPro 3100 (i)

pH elektroda

Návod k obsluze

InProaISMjsouregistrovanéochrannéznámkyspolečnosti

METTLER TOLEDO veŠvýcarsku,USA,Evropskéunii

adalšíchpětizemích.

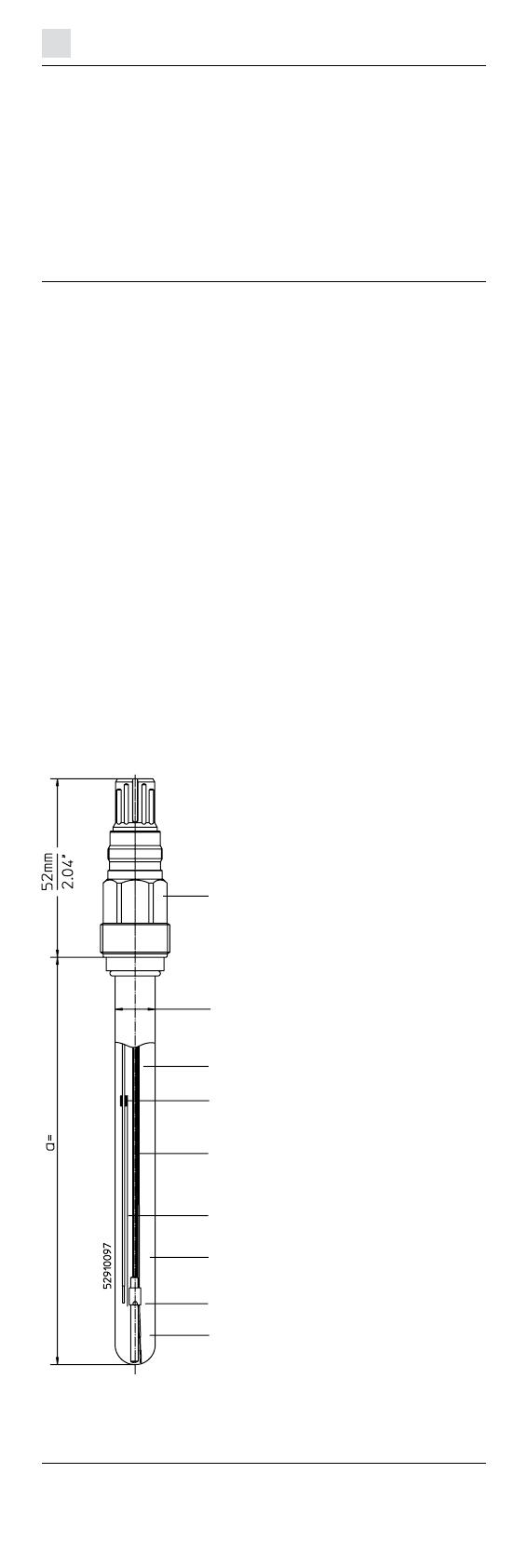

12 mm

0.47"

Typkonektoru(zde:VP)

Elektrolytdomůstku

Lapačiontůstříbraamembrána

Referenčníelektrolyt

Teplotníčidlo

Stříbrnýreferenčníprvek

Membrána

SklocitlivénapH

cs Návod k obsluze

InPro 3100 (i) pH electrode 3

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

1 Úvod

pH elektrody METTLER TOLEDO InPro™ 3100(i) jsou

nízkoúdržbové, autoklávovatelné měřicí elektrody odolné

proti tlaku s referenčním elektrolytem gelového typu.

Referenční prvek obsahuje lapač iontů stříbra, který

zabraňujesráženísíranustříbrnéhonamembráně.Elektrody

InPro3100majíintegrovanéteplotníčidlourčenépředevším

k automatické kompenzaci teploty u signálu pH během

kalibrace a provozu.

Elektrody InPro 3100(i) jsou určeny především k měření

hodnoty pH za mírného tlaku (<6bar) v biotechnických

pro c esech.L zejepoužívatvp r ů mysl ovéfer m e n t a ci,pilotníc h

provozech a laboratorních podmínkách. Jsou určeny

zejménaproprocesy, v nichž jenezbytná mezisterilizace

neboprůběžnéautoklávování.

Tentonávodkobsluzesipředuvedenímzařízenídoprovozu

pečlivěprostudujte.Zajistítetakbezproblémovýprovoz.

2 Bezpečnostní pokyny

Elektrody InPro 3100(i) jsou určeny výhradně k účelu

popsanému v odst. 1 výše. Elektroda obsahuje některé

skleněnédílyavyžadujeopatrnoumanipulaci.Přičištění

nebokalibrováníelektrodypomocíkyselýchnebozásaditých

roztoků jenutné používatochranné brýlearukavice.Pro

manipulaciselektrodouplatímístníbezpečnostnípředpisy.

Postupujtepodlepřiloženýchpokynůkinstalacidooblastí

snebezpečímvýbuchu.

Doporaučujeme používat elektrodu pouze v kombinaci

s originálními díly od společnosti METTLER TOLEDO.

Provozaúdržbu zařízeníbymělprovádětpouzeškolený

personálseznámenýsnávodemkjehoobsluze.

3 Popis produktu

Nápisnakaždéelektroděobsahujenásledujícíinformace:

METTLER TOLEDO Výrobceelektrody

InPro™ 310X iUD / SG / yyy / zzz Označenítypu,X=skleněná

membrána,i=digitálníISM,

UD=dnemvzhůru/SG=pomocná

elektroda/yyy=délkatyče

vmm/zzz=typteplotníhočidla

combinationpH Typelektrody(kombinovanápH)

pH 0 … 14 RozsahměřenípH

0…80°C/140°C(130°C) Teplotnírozsahproprovoz/

sterilizaci(platípro3100UD)

OrderNo.5200XXXX Objednacíčíslo

SEV14ATEX0168X Identikaceačíslocertikátu

IECExSEV14.0025X Identikaceačíslocertikátu

IS/I,II,III/1/ABCDEFG/T6 SchváleníFM

Seeinstructionmanual! Pokyny(dodržujtepokyny

uvedenévnávodukobsluze)

Všemelektrodámjenavícpřidělenovýrobníčíslouvedené

na připojovací hlavici, které umožňuje jejich přesnou

identikaciasledování.

InformaceocertikaciUKEXuvádíanglickáčást

tétopříručky.

cs

4 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

4 Instalace a uvedení do provozu

1. Povybalenízkontrolujte,zdaskloelektrodycitlivéna

pHajejídříknejsoumechanickypoškozené.Veškeré

závady neprodleně oznamte svému dodavateli

produktůMETTLERTOLEDO.

2. Otevřete víčko plnicího otvoru a elektrodu krátce

propláchněte deionizovanou vodou. Po propláchnutí

elektrodu osušte lehkým přiložením hadříku. Netřete

hadříkosklocitlivénapH,mohlobydojítkvytvoření

elektrostatického náboje, který by prodloužil reakční

dobu.

3. Zkontrolujte, zda prostor za sklem citlivým na pH

neobsahuje vzduchové bubliny. Případné bubliny

odstraňte lehkým protřepáním elektrody ve svislém

směru.

4. Informaceomontážielektrodyjsouuvedenyvnávodu

kobsluzepříslušnéhokrytu.

5. Připojte elektrodu k převodníku pH pomocí kabelu

spříslušnýmkonektorem(konektorVPproInPro3100).

Další informace jsou uvedeny veschématu připojení

arozmístěnísvorekpřiloženémkekabelu.

6. ChytréelektrodyISM™jakoInPro310Xipodporujífunkci

Plug and Measure a rozšířenou diagnostiku. Montáž

systémuISM,jehouvedenídoprovozuaprovozjsou

popsány v pokynech k obsluze převodníku, modulu

akabelu.

5 Provoz

5.1 Kalibrace elektrody a převodníku pH

ProelektroduInPro 3100(i)doporučujemedvoubodovou

kalibracipH.Předkalibracínejprveotevřetevíčkoplnicího

otvoru.Chcete-lipodlouhépřepravě,dlouhémskladování

nebopředkalibracízkrátitreakčnídobu,ponořteelektrodu

do pufru pH 7, pH 4 a znovu pH 7, vždy asi na jednu

minutu. Poté ji ponořte postupně do dvou různých

pufračníchroztokůsdanýmireferenčnímihodnotamipHa

převodníkkalibrujtenatytopufrovacíhodnoty.Zaběžných

okolností nejprve pufrem pH 7 určete nulový bod a pak

pufrempH 4 nebo9určetesklon.Vpřípaděpřevodníků

řízených mikroprocesorem, které umí rozpoznat pufr,

nehraje pořadí dvou zvolených pufrovacích roztoků roli.

Kdykolijetomožné,mělobybýtkpřevodníkupřipojeno

teplotníčidlo(uInPro3100jeintegrované)saktivovaným

automatickýmměřenímteploty.Dalšípodrobnostinajdete

vnávodukpřevodníku.

5.2 Sterilizace elektrody

Elektrodu InPro 3100(i) lze sterilizovat v autoklávu (po

odstraněníčervenéochrannékrytky),neboinsitupárouči

přehřátýmfermentačnímmédiem.Sterilizačníteplotanesmí

přesáhnout140°C.Nadměrnádobasterilizace(například

t > 30 min. při 140°C) může výrazně zkrátit životnost

elektrody.Opakovanésterilizaceaautoklávováníelektrody

mohou vést k mírnému zbarvení elektrolytu. Tato změna

barvynemážádnývlivnafunkcielektrody.

5.3 Teplotní čidlo pro InPro 3100 (analogová verze)

Integrované teplotní čidlo Pt 100/1000 elektrody

InPro3100jeurčenopředevšímkautomatickékompenzaci

teplotyprosignálpH.Nesloužítedykpřesnéindikaciani

regulaci procesní teploty. Pokud si tuto možnost přejete

vyzkoušet, zkontrolujte, zda váš převodník umožňuje

indikaciteplotyopožadovanépřesnostiamávolnývýstup

pro příslušný signál. Je možné, že bude nutné provést

kalibracisignáluteploty.

cs

InPro 3100 (i) pH electrode 5

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

6 Údržba

1. Pokaždémvýrobnímcykluopatrněopláchnětešpičku

amembránuelektrodydeionizovanouvodou.Natěchto

částechnesmízažádnýchokolnostízaschnoutměřicí

roztok!

2. Pokudelektrodunepoužíváte,skladujtejitak,abybyla

její špička a membrána celá ponořena v elektrolytu

9823 /3MKClnebo9816/Viscolyt™.

3. Pravidlo uvedené v bodu 2) výše zároveň platí,

pokudjeelektrodaskladovánanamontovanávkrytu.

Skladovacíelektrolytjevšaknutnénepatrněupravit2

dílypufračníhoroztokuspH9,2v10dílechelektrolytu,

abynedocházelokekorozičástíkrytu.

4. Pokudbybylaelektrodaomylemněkolikdnískladována

vsuchu,namočtejipředpoužitímnaněkolikhodindo

běžnéhoskladovacíhoelektrolytu.

5. Příležitostně kontrolujte konektor na možný výskyt

stop vlhkosti. V případě potřeby jej pečlivě vyčistěte

deionizovanouvodouneboalkoholemapotéopatrně

osušte.

7 Odstraňování potíží (dlouhá reakční doba,

nedostatečná citlivost atd.)

Skleněnou membránu lze znovu aktivovat roztokem

kyseliny uorovodíkové (obj. č. 51 319 053). Špičku

elektrody(pouzečástsesklemcitlivýmnapH)ponořtedo

roztokukyselinyuorovodíkovénaasi5minut,následně

jiihneddůkladněopláchnětedeionizovanouvodouapoté

ponořteažpomembránudopufračníhoroztokupH4(viz

bod6)na12hodin.

Případnébílkovinnéusazeninyanánosynamembránělze

odstranitnašímspeciálnímčističemelektrod(obj.č.51340

068).Utohototypuelektrodneníobvyklenutnépoužívat

čističmembrán(obj.č.51340070),neboťintegrovaný

lapačiontůstříbrabráníznečištěnísíranemsodným.

Konektor kontrolujte na možný výskyt stop vlhkosti.

V případě potřeby jej pečlivě vyčistěte deionizovanou

vodouneboalkoholemapakjejopatrněosušte.

8 Ochrana životního prostředí

Odpadní elektrická zařízení by neměla být likvidována

společněsesměsnýmodpadem.Výrobekpředejtekrecy-

klaci,pokudexistujesběrnémístoodpadníchelektrických

zařízení.Proradytýkajícíserecyklaceseobraťtenapří-

slušnémístníúřadynebonaprodejce.

9 Záruka

Záruční doba na výrobní vady činí 12 měsíců od data

dodání.

cs

6 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

1 Introduktion .................................................................... 7

2 Sikkerhedsanvisninger ..................................................... 7

3 Produktbeskrivelse .......................................................... 7

4 Installation og idriftsættelse .............................................. 8

5 Drift ................................................................................ 8

5.1 KalibreringafelektrodeogpH-transmitter .......................... 8

5.2 Sterilisering af elektroden ................................................. 8

5.3 TemperatursensoreniInPro3100(analogudgave)............. 8

6 Vedligeholdelse ............................................................... 9

7 Fejlnding(langsomresponstid,utilstrækkelig

følsomhedosv.) .............................................................. 9

8 Bortskaffelse ................................................................... 9

9 Garanti ........................................................................... 9

Indhold

da

InPro 3100 (i)

pH-elektrode

Instruktionsvejledning

InProogISMerregistreredevaremærker

tilhørendeMETTLER TOLEDO GroupiSchweiz,

USA,EUogyderligerefemlande.

12 mm

0.47"

Tilslutningstype(her:VP)

Broelektrolyt

Sølvionfældeogdiafragma

Referenceelektrolyt

Temperatursensor

Argenthal-referenceelement

Diafragma

pH-følsomtglas

da Brugsanvisning

InPro 3100 (i) pH electrode 7

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

1 Introduktion

InPro™ 3100(i)-pH-elektroderne fra METTLER TOLEDO er

måleelektrodermedlavvedligeholdelse,derkanautokla-

veresogertrykresistenteogudstyretmedenreferenceelek-

trolytafgel-typen.Referenceelementetanvenderensølvi-

onfælde,derforhindrersølvsuldudfældningpådiafragma.

VedInPro3100erderindbyggetentemperatursensor,som

hovedsageligt er beregnet til muligheder for automatisk

temperaturkompenseringafpH-signaletunderkalibrering

og drift.

InPro3100(i)-elektroderneerprimærtberegnettilmåling

af pH-værdien i biotekniske processer ved moderat tryk

(<6bar).Dekanbrugesunderindustrielfermentering,pilot-

oglaboratorieforholdogerspecieltberegnettilprocesser,

hvor mellemliggende sterilisering eller autoklavering er

uomgængelig.

Læs venligst denne betjeningsvejledning omhyggeligt før

idriftsættelseforatsikreproblemfrianvendelse.

2 Sikkerhedsanvisninger

InPro3100(i)-elektroderneerudelukkendeberegnettildet

formål,dererangivetiafsnit1ovenfor.Elektrodenbestår

delvistafglasogskalhåndteresforsigtigt.Hviselektroden

skal rengøres eller kalibreres ved hjælp af syreholdige

eller alkaliske opløsninger, skal der bæres øjenværn og

sikkerhedshandsker.Lokalesikkerhedsbestemmelserskal

overholdesvedhåndteringafelektroden.Følgdevedlagte

retningslinjerforinstallationifarligeområder.

Vianbefaler,atdukunanvenderelektrodensammenmed

originale reservedele fra METTLER TOLEDO. Drift og vedli-

geholdelsemåkunudføresafuddannetpersonaleogmed-

arbejdere,somharlæstogforståetbetjeningsvejledningen.

3 Produktbeskrivelse

Inskriptionenpåhverenkeltelektrodeindeholderfølgende

oplysninger:

METTLER TOLEDO Elektrodeproducenten

InPro™ 310X iUD / SG / yyy / zzz Typeangivelse;X=membranglas;

i=ISMDigital;UD=bunden

opad/SG=hjælpeelektrode/

yyy=rodlængdeimm/

zzz=temperatursensortype

combinationpH Elektrodetype(pH-kombination)

pH 0 … 14 pH-måleområde

0…80°C/140°C(130°C) Temperaturområdefordrift/

sterilisering(forInPro3100UD)

OrderNo.5200XXXX Bestillingsnummer

SEV14ATEX0168X Identikationogcertikatnr.

IECExSEV14.0025X Identikationogcertikatnr.

IS/I,II,III/1/ABCDEFG/T6 FM-godkendt

Seeinstructionmanual! Instruktion (følg

betjeningsvejledningen)

Derudover har hver enkelt elektrode et serienummer på

tilkoblingshovedetforatmuliggøreidentikationogsporing.

Sedenengelskedelafdennemanualvedrørende

UKEX-certiceringen.

da

8 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

4 Installation og idriftsættelse

1. Underudpakningkontrollereselektrodenformekaniske

skaderpådetpH-følsommeglasogskaftet.Rapportér

omgåendeeventuelleskadertildinMETTLERTOLEDO-

leverandør.

2. Fjern vandhætten, og skyl kort elektroden med

aoniseret vand. Efter skylning må elektroden kun

duppestørmed enserviet.Undgå atgnubbepådet

pH-følsommeglas,dadetkanresultereielektrostatisk

ladningoglangsommeresponstider.

3. Kontrollér området bag det pH-følsomme glas for

luftbobler,ogfjerndissevedforsigtigtatrysteelektroden

lodret op og ned.

4. Se instruktionsvejledningen til det relevante kabinet

vedrørende installation af elektroden.

5. ForbindelektrodentilpH-transmitterenvedhjælpafet

kabelmeddenpassendetilslutning( VP-tilslutningtilIn-

Pro3100).Seledningsførings-ogterminaldiagrammet,

derblevleveretsammenmedkablet.

6. Intelligente ISM®-elektroder,såsomInPro310Xi,mulig-

gør“PlugandMeasure”samtudvidetdiagnosticering.

Følginstruktionernefortransmitter,modulogkabelved

installation,idriftsættelseogbetjeningafISM-systemet.

5 Drift

5.1 Kalibrering af elektrode og pH-transmitter

TilInPro3100(i)anbefalesdetatbrugeen2-punktspH-ka-

librering.Vandhætten fjernes før kalibrering.For atfå en

hurtigereresponstidpåelektrodenefterlangetransport-og

opbevaringsperioder,ogførkalibrering,dyppeselektroden

ibufferpH7,bufferpH4ogbufferpH7igen,hvergangi

ca.étminut.Elektrodendyppesdereftertrinvistitoforskel-

ligebufferopløsningermedgivnepH-referenceværdier,og

transmitteren kalibreres i henhold til disse bufferværdier.

Normalt begynder du med buffer pH 7 for at bestemme

nulpunktet, og derefter bruges buffer pH 4 eller 9 til at

bestemmehældning.Formikroprocessorbaseredetrans-

mittere med buffergenkendelse er rækkefølgen af de to

valgte bufferopløsninger irrelevant. Når som helst det er

muligt,skalderkoblesentemperatursensor(tilInPro3100

den integrerede sensor) til transmitteren og “automatisk

temperaturmåling”vælgesdér.Sevenligsttransmitterens

instruktionsmanualforyderligereoplysninger.

5.2 Sterilisering af elektroden

InPro3100(i)-elektrodenkansteriliseresentenvedhjælpaf

autoklavering(fjerndenrødebeskyttelseshætte)ellerved

hjælpafin-situ-steriliseringmeddampelleretoveropvarmet

fermenteringsmedie. Steriliseringstemperaturer på over

140°C er ikke tilladt, og overdreven lang steriliseringstid

(f.eks.t>30min.ved140°C)kanforkorteelektrodenslevetid

betydeligt.Gentagensteriliseringog/ellerautoklaveringaf

elektrodenkanmedføreenletmisfarvningafelektrolytten.

Farveændringenpåvirkerikkeelektrodensfunktion.

5.3 Temperatursensoren i InPro 3100 (analog udgave)

Den indbyggede Pt100/1000-temperatursensor i InPro

3100erhovedsageligtberegnettilautomatisktemperatur-

kompenseringafpH-signaletogikketilnøjagtigellersikker

temperaturindikation eller kontrol af procestemperaturen.

Hvisdualligevelønskeratprøvedette,skaldukontrollere,at

dintransmitterhardennødvendigetemperaturindikations-

nøjagtighedogenfriudgangtilsignalet.Derudoverkandet

værenødvendigtatkalibreretemperatursignalet.

da

InPro 3100 (i) pH electrode 9

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

6 Vedligeholdelse

1. Skyl forsigtigt elektrodens spids og diafragma med

aoniseret vand efter hver enkelt produktionscyklus.

Måleopløsningmåunderingenomstændighederfålov

tilattørreindpådissedele!

2. Når elektroden ikke er i brug, skal den opbevares

medelektrodensspidsogdiafragmagodtnedsænket

i9823 /3MKCl-eller9816/Viscolyt™-elektrolyt.

3. Hvis elektroden opbevares monteret i kabinettet,

gældersammeregelsomunderpunkt2ovenfor,men

opbevaringselektrolyttenskalændresensmule,med2

delebufferopløsningpH9,2til10deleelektrolyt.Dette

gøresforatundgåkorrosionpåkabinetdelene.

4. Hvisenelektrodevedetuheldopbevaresitørtilstand

i et par dage, skal den ligge i blød i den normale

opbevaringselektrolytieretimer,førdenkananvendes.

5. Kontrollér lejlighedsvist tilslutningen for eventuelle

sporaffugt.Omnødvendigtrensesdengrundigtmed

aoniseretvandellerspritogtørresderefterforsigtigt.

7 Fejlnding (langsom responstid,

utilstrækkelig følsomhed osv.)

Glasmembranen kan genaktiveres med en HF-opløsning

(bestillingsnr.51319053).Elektrodensspids(kundenpH-

følsommeglasdel)nedsænkesiHF-opløsningiomkring5

minutter.Derefterskyllesdenomgåendeoggrundigtmed

aoniseretvand,hvorefterdenopbevaresibufferopløsning

pH4(sepunkt6herover)optildiafragmai12timer.

Eventuelproteinudfældningogblokeringafdiafragmakan

behandlesmedvoresspecielleelektroderenser(bestillings-

nr. 51340 068).Menanvendelse af diafragmarenseren

(bestillingsnr.51340070)ernormaltunødvendigtpåden-

neelektrodetype,dadenindbyggedesølvionfældeforhin-

drerdannelsenafsølvsuldkontaminering.

Kontrollérogsåtilslutningenforeventuellesporaffugt.Om

nødvendigtrensesgrundigtmedaoniseretvandellersprit.

Derefter tørres der forsigtigt.

8 Miljøbeskyttelse

Elektriske affaldsprodukter må ikke bort-

skaffes med husholdningsaffald. Send

venligst til genbrug, hvor disse faciliteter

ndes.Spørgdelokalemyndighederellerdin

forhandlerområdvedrørendegenbrug.

9 Garanti

Påproduktionsfejl;12månederefterlevering.

da

10 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

1 Einleitung.......................................................................11

2 Sicherheitshinweise ........................................................11

3 Produktbeschreibung ......................................................11

4 InstallationundInbetriebnahme .......................................12

5 Betrieb ........................................................................... 12

5.1 KalibrierungderElektrodeunddespH-Transmitters ...........12

5.2 Sterilisation der Elektrode ................................................12

5.3 TemperaturfühlerderInPro3100(analogeVersion) ..........13

6 Wartung ........................................................................13

7 BehebungvonStörungen(langsamesAnsprechen,

ungenügendeSensitivitätusw.) ........................................13

8 Entsorgung ....................................................................13

9 Garantie ........................................................................13

Inhaltsverzeichnis

de

InPro 3100 (i)

pH-Elektrode

Betriebsanleitung

InProundISMsindeingetrageneWarenzeichen

derMETTLER TOLEDO GruppeinderSchweiz,denUSA,

derEuropäischenUnionundweiterenfünfLändern.

12 mm

0.47"

Steckkopf-Typ(hier:VP)

Brückenelektrolyt

SilberionenfalleundDiaphgragma

Bezugselektrolyt

Temperaturssensor

ArgenthalBezugselement

Diaphragma

pH-sensitivesGlas

de Betriebsanleitung

InPro 3100 (i) pH electrode 11

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

1 Einleitung

Die METTLER TOLEDO Einstabmessketten InPro™

3100(i) sind wartungsarme, autoklavierbare und

druckbeständige pH-Elektroden mit einem gelförmigen

Bezugselektrolyt. Bei diesem Elektrodentyp ist das

Bezugselement mit einer Silberionensperre ausgerüstet,

um das Ablagern von Silbersuld am Diaphragma zu

verhindern.InPro 3100-Elektroden sind mit eingebautem

Temperaturfühler ausgestattet, um die automatische

Temperaturkompensation des pH-Signals während der

KalibrationunddesBetriebsderElektrodezuermöglichen.

InPro 3100(i)-Elektroden sind hauptsächlich für

die pH-Messung in biotechnischen Prozessen bei

moderaten Prozessdrucken (<6bar) konzipiert

worden. Sie sind besonders für Prozesse bestimmt,

wo die Zwischensterilisation beziehungsweise das

Zwischenautoklavieren unerlässlich ist, und können

sowohl in der industriellen Fermentation wie auch unter

Pilot-undLaborbedingungeneingesetztwerden.

Bitte lesen Sie diese Betriebsanleitung vor der Inbetrieb-

nahmeaufmerksamdurch,umeineeinwandfreieFunktion

sicherzustellen.

2 Sicherheitshinweise

Die InPro 3100(i)-Elektroden sind nur für den unter §1

erwähntenEinsatzzweckbestimmt.DieElektrodenbestehen

teilweiseausGlasundsolltenvorsichtigbehandeltwerden.

BeiderReinigungoderKalibrierungvonElektrodenmittels

säure- oder alkalihaltigen Lösungen sollten sowohl eine

SchutzbrillealsauchSchutzhandschuhegetragenwerden.

FürdieHandhabungderElektrodengeltenfernerdielokalen

Sicherheitsvorschriften. Für eine Installation im Ex-Bereich

beachtenSiebittediebeigelegtenRichtlinien.

WirempfehlenIhnen,dieElektrodenurinZusammenhang

mit Originalteilen von METTLER TOLEDO zu betreiben.

Die Bedienung und der Service sollten ausschliesslich

durch geschultes Personal und Mitarbeiter, welche die

Bedienungsanleitung gelesen und verstanden haben,

durchgeführtwerden.

3 Produktbeschreibung

Der Aufdruck auf jeder Elektrode enthält folgende

Informationen:

METTLER TOLEDO Hersteller der Elektrode

InPro™ 310X iUD / SG / yyy / zzz Typenbezeichnung;X=Membran-

glas;i=ISMDigital;UD=Einbau

vonunten/SG=

Hilfselektrode/yyy=Schaftlängein

mm/zzz=Artdes

Temperaturfühlers

combinationpH ArtderElektrode

(pH-Kombination)

pH0…14 pH-Messbereich

0…80°C/140°C(130°C) TemperaturbereichfürBetrieb/

Sterilisation(fürInPro3100UD)

OrderNo.5200XXXX Bestellnummer

SEV14ATEX0168X KennzeichnungundNummer

derBescheinigung

IECExSEV14.0025X KennzeichnungundNummer

derBescheinigung

IS/I,II,III/1/ABCDEFG/T6 FMgeprüft

Seeinstructionmanual! Hinweis(BeachtenSiedie

Betriebsanleitungen)

InformationenzurUKEX-ZertizierungndenSieim

englischenTeildiesesHandbuchs.

de

12 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

Zusät zlichistje d eElekt rodemiteinerSeriennummera u fdem

Steckkopfversehen,umdieIdentikation/Rückverfolgbarkeit

zuermöglichen.

4 Installation und Inbetriebnahme

1. PrüfenSiedieElektrodebeimAuspackenaufeventuelle

mechanische Defekte des pH-sensitiven Glases und

des Schaftes. Eventuelle Schäden sind sofort Ihrem

METTLERTOLEDOLieferantenzumelden.

2. Entfernen Sie die Wässerungskappe und spülen Sie

die Elektrode kurz mit deionisiertem Wasser. Nach

demAbspülensolldieElektrodenurabgetupftwerden.

Ein Abreiben des pH-sensitiven Glases kann die

Ansprechzeit durch elektrostatische Auadung stark

erhöhen.

3. EntfernenSiegegebenenfallsLuftblasenimRaumhinter

dempH-sensitivenGlasdurchleichteSchleuderbewe-

gungeninsenkrechterEbene.

4. SetzenSiedieElektrodeindieArmaturein,wieinder

AnleitungzurArmaturbeschrieben.

5. Verbinden Sie Elektrode und den pH-Transmitter mit

dem dafür vorgesehenen Kabel (VP-Steckverbindung

fürInPro3100).BeachtenSiedasdemKabelbeigelegte

Verdrahtungs-undAnschlussschema.

6. Intelligente ISM®-Elektroden wie InPro 310Xi ermög-

lichen«PlugandMeasure»underweiterteDiagnostik.

Für die Installation, Inbetriebnahme und Betrieb des

ISM-SystemsbeachtenSiebittedieAnleitungdesTrans-

mitters,desModulsunddiedesKabels.

5 Betrieb

5.1 Kalibrierung der Elektrode und des pH-Transmitters

Für die Elektrode InPro 3100(i) wird eine 2-Punkt-

Kalibrierung empfohlen. Zuerst die Wässerungskappe

entfernen.UmdieAnsprechzeitderElektrodenachlängerer

Transport-undLagerungszeit zubeschleunigen,undvor

derKalibrierung,tauchenSiedieElektrodenacheinanderfür

etwa1MinuteinPufferlösungenpH7,pH4undnochmals

pH7ein.DieElektrodewirddannderReihenachinzwei

verschiedene Pufferlösungen mit bekannten pH-Werten

eingetauchtundderpH-TransmitteraufdiesePufferwerte

kalibriert.NormalerweisebeginntmanmitderPufferlösung

pH7,u md enN ull -P un kter mit t elnzu kö nn en,g efo lg tv on der

PufferlösungpH4oderpH9,umdieSteilheitzubestimmen.

BeiTransmitternmitMikroprozessoren,diediePufferlösung

automatischerkennenkönnen,spieltdieReihenfolgeder

gewähltenPufferlösungenkeineRolle.Woimmermöglich,

sollteeinTemperaturfühler(beiInPro3100dereingebaute

Pt-Sensor) an den Transmitter angeschlossen und der

Modus «automatische Temperaturmessung» gewählt

werden. Für weitere Angaben beachten Sie bitte die

BetriebsanleitungdesTransmitters.

5.2 Sterilisation der Elektrode

DieSterilisationderElektrodeInPro3100(i)kannentweder

mittels Autoklavieren (rote Schutzkappe entfernen) oder

durch in-situ Sterilisation mit Dampf beziehungsweise

überhitztem Fermentationsmedium durchgeführt werden.

Sterilisationstemperaturen über 140°C sind unzulässig,

undübermässigeSterilisationszeiten(z.B.t>30Minuten

bei 140°C) können die Lebensdauer der Elektrode stark

beeinträchtigen. Wiederholte Sterilisation und/oder

Autoklavierung der Elektrode können zur Verfärbung des

Elektrolytesführen.EineeventuelleFarbänderunghataber

keinerleiEinussaufdieFunktionderElektrode.

de

InPro 3100 (i) pH electrode 13

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

5.3 Temperaturfühler der InPro 3100 (analoge Version)

DerinderInPro3100integriertePt100/1000-Temperatur-

fühleristhauptsächlichfürdieautomatischeKompensa-

tiondespH-Signalsundnichtfüreinegenaueundsichere

Temperaturanzeigeoder-steuerungderProzesstemperatur

vorgesehen.SolltenSiedenTemperaturfühlerderElektro-

defürdieProzessüberwachungoder-regelungverwenden

wollen,solltenSiesicherstellen,dassIhrTransmittereinen

freien Signalausgang aufweist und über die gewünschte

Genauigkeitverfügt.DarüberhinauskanneineTemperatur-

kalibrationdesgesamtenSystemsnotwendigwerden.

6 Wartung

1. Nach jedem Arbeitszyklus sind Elektrodenspitze und

Diaphragma(s) sorgfältig mit deionisiertem Wasser

abzuspülen. Das Antrocknen von Rückständen der

gemessenenLösungaufdiesenTeilenistunbedingtzu

vermeiden!

2. WenndieElektrodenichtinGebrauchist,wirdsiemitder

Elektrode nspitzeunddemDiaphragmainein enBe hälter

mit Elektrolyt (9823/3M KCl oder 9816/Viscolyt™)

eingetauchtgelagert.

3. WirddieElektrodeinihrerArmaturaufbewahrt,geltendie

unterPunkt2beschriebenenRegeln,wobeijedochdas

ElektrolytfürdieAufbewahrungleichtmodiziertwerden

mu ss (2 Te ileP uf f erl ös un gpH 9,2zu10 Te ile nEle kt roly t),

umeineKorrosionderArmaturenteilezuvermeiden.

4. WirdeineElektrodeversehentlicheinigeTagetrocken

gelagert,musssievorGebrauchmehrereStundenim

normalenAufbewahrungselektrolytgewässertwerden.

5. DerSteckkopfsolltegelegentlichaufmöglicheSpuren

von Feuchtigkeit überprüft werden. Falls notwendig,

reinigen Sie ihn gründlich mit deionisiertem Wasser

oder Alkohol und trocknen Sie ihn anschließend

vorsichtigab.

7 Behebung von Störungen (langsames

Ansprechen, ungenügende Sensitivität usw.)

Die Glasmembrankann mit einer HF-Lösung(Bestell-Nr.

51319053)reaktiviertwerden.DieElektrodenspitze(nur

derpH-sensitiveGlasteil)wirdfüretwa5Minuten in die

HF-Lösungeingetaucht,sofortgründlichmitdeionisiertem

Wassergespült und anschliessend während 12 Stunden

biszurHöhedesDiaphragmasineinerPufferlösungpH4

(siehePunkt6oben)aufbewahrt.

Proteinverschmutzungen des Diaphragmas können mit

dem Spezialreiniger (Bestell-Nr. 51 340 068) behandelt

werden. Eine Reinigung mit dem Diaphragmareiniger

(Bestell-Nr.51340070)istnormalerweisenichtnötig,da

dieeingebauteSilberionensperreSilbersulphidverschmut-

zungenverhindert.

ÜberprüfenSieauchdenSteckkopfnachmöglichenSpuren

von Feuchtigkeit. Falls notwendig, solche Spuren mit

deionisiertemWasserodermitAlkoholvollständigentfernen

undanschliessendSteckkopfsorgfältigabtrocknen.

8 Umweltschutz

Elektroaltgeräte dürfen nicht zusammen mit

dem Hausmüll entsorgt werden. Bitte führen

SiediesemöglichstEinrichtungenzurWieder-

verwertung zu. Wenden Sie sich an Ihre zu-

ständigeBehördeoderIhrenFachhändler,um

HinweisezurWiederverwertungzuerhalten.

9 Garantie

12MonatenachLieferungaufFabrikationsfehler.

de

14 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

1 Introduction ...................................................................15

2 Safetyinstructions ..........................................................15

3 Product description ......................................................... 15

4 Installationandcommissioning .......................................16

5 Operation .......................................................................16

5.1 CalibrationoftheelectrodeandpHtransmitter ..................16

5.2 Sterilization of electrode ..................................................16

5.3 TemperaturesensorofInPro3100(analogversion) ...........16

6 Maintenance ..................................................................17

7 Trouble-shooting(sluggishresponsetime,insufcientsensiti-

vityetc.) ........................................................................17

8 Disposal ........................................................................17

9 Guarantee ......................................................................17

Contents

en

InPro 3100 (i)

pH Electrode

Instruction Manual

InProandISMareregisteredtrademarks

of METTLER TOLEDO GroupinSwitzerland,theUSA,

theEuropeanUnionandafurthervecountries.

12 mm

0.47"

Connectortype(here:VP)

Bridgeelectrolyte

Silver-iontrapanddiaphgragm

Referenceelectrolyte

Temperaturesensor

Argenthalreferenceelement

Diaphragm

pH sensitive glass

en Instruction Manual

InPro 3100 (i) pH electrode 15

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

1 Introduction

The METTLERTOLEDOInPro™ 3100 (i) pH electrodes are

low-maintenance, autoclavable and pressure-resistant

measuringelectrodeswithagel-typereferenceelectrolyte.

The reference element incorporates a silver-ion trap to

preventsilversuldeprecipitationonthediaphragm.Incase

ofInPro3100,atemperaturesensorisintegrated,mainlyfor

automatictemperaturecompensationpossibilitiesofthepH

signal during calibration and operation.

The InPro 3100(i) electrodes are mainly designed for

the measurement of pH value in biotechnical processes

at moderate pressures (<6bar). It can be used under

industrial fermentation, pilot and laboratory conditions,

and is particularly intended for those processes where

intermediatesterilizationorautoclavingisindispensable.

Pleasereadthroughtheseoperatinginstructionscarefully

beforecommissioning,inordertoensuretrouble-freeuse.

2 Safety instructions

The InPro 3100(i) electrodes are intended solely for the

purposedescribedin§1above.Theelectrodeconsistspartly

ofglassandshouldbehandledcarefully.Iftheelectrodeis

tobecleanedorcalibratedusingacidoralkalinesolutions,

safetygoggles andglovesshould be worn.Local safety

regulationsareapplicabletothehandlingoftheelectrode.

Pleasefollowtheguidelinesenclosedforaninstallationin

theEx-zone.

We recommend that you only operate the electrode in

combination with original parts from METTLER TOLEDO.

Operationandmaintenanceshouldbecarriedoutonlyby

trainedpersonnelandstaffwhohavereadandunderstood

theoperatinginstructions.

3 Product description

The inscription on each electrode contains the following

information:

METTLER TOLEDO Manufactureroftheelectrode

InPro™ 310X iUD / SG / yyy / zzz Typedesignation;X=membrane

glass;i=ISMDigital;UD=upside

down/SG=ancillaryelectrode/

yyy=rodlengthinmm/zzz=type

oftemperaturesensor

combinationpH Typeofelectrode

pH0…14 pHmeasurementrange

0…80°C/140°C(130°C) Temperaturerangeforoperation/

sterilization(forInPro3100UD)

OrderNo.5200XXXX Ordernumber

SEV14ATEX0168X Identicationandnumber

ofcerticate

IECExSEV14.0025X Identicationandnumber

ofcerticate

CML22UKEX2108X Identicationandnumber

ofcerticate

IS/I,II,III/1/ABCDEFG/T6 FMapproved

Seeinstructionmanual! Instruction(Observethe

operating instructions)

Inadditioneachelectrodeisallocatedaserialnumberon

theplug-inheadtoenableidenticationandtraceability.

en

16 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

4 Installation and commissioning

1. On unpacking, check the electrode for mechanical

damage of the pH sensitive glass and shaft. Report

any damage immediately to your METTLER TOLEDO

supplier.

2. Removethewateringcapandbrieyrinsetheelectrode

withdeionizedwater.Afterrinsing,theelectrodeshould

onlybedabbeddrywithatissue.DonotrubthepH

sensitive glass, since this can lead to electrostatic

chargingandsluggishresponsetimes.

3. CheckthespacebehindthepHsensitiveglassforthe

presenceofanyairbubblesandremovesamebygently

swingingtheelectrodeinaverticalplane.

4. Please refer to the instruction manual of the relative

housinginordertoinstalltheelectrode.

5. Connect the electrode to the pH transmitter, using a

cable with the appropriate connector (VP connector

forInPro3100).Pleaserefertothewiringandterminal

diagramaccompanyingthecable.

6. Intelligent ISM®electrodessuchasInPro310Xienable

“Plug and Measure” and extended diagnostics. For

installation, commissioning and operation of the

ISM system please observe the instructions for the

transmitter,moduleandcable.

5 Operation

5.1 Calibration of the electrode and pH transmitter

FortheInPro3100(i)electrodea2-pointpHcalibrationis

recommended.Beforecalibration,rstremovethewatering

cap.Tospeeduptheresponsetimeoftheelectrodeafter

longtransportandstorageperiods,andbeforecalibration,

diptheelectrodeintobufferpH7,bufferpH4andbufferpH

7again,eachtimeforaboutoneminute.Theelectrodeis

thendippedsuccessivelyintotwodifferentbuffersolutions

withgivenpHreferencevaluesandthetransmittercalibrated

tothesebuffervalues.NormallyyoustartwithbufferpH7

fordeterminingthe0-pointandthenbufferpH4or9for

determiningtheslope.Inthecaseofmicroprocessor-based

transmitters with buffer recognition, the order of the two

chosenbuffersolutions isirrelevant.Wheneverpossible,

atemperaturesensor(forInPro3100theintegratedone)

should be connected to the transmitter and “automatic

temperaturemeasurement”selectedthere.Pleasereferto

theinstructionmanualofthetransmitterforfurtherdetails.

5.2 Sterilization of electrode

TheInPro3100(i)electrodecanbesterilizedeitherthrough

autoclaving (remove red protection cap) or through in-

situ sterilization with steam or superheated fermentation

medium. Sterilization temperatures above 140°C are not

allowed,andexcessivesterilizationtime(forinstancet>30

minat140°C)could notably shorten the life timeof the

electrode.Repeatedsterilizationand/orautoclavingofthe

electrodecanleadtoaslightcolorationoftheelectrolyte.

This color change does not effect the functioning of the

electrode.

5.3 Temperature sensor of InPro 3100 (analog version)

The integrated Pt100/1000 temperature sensor in the

InPro3100isprimarilyintendedforautomatictemperature

compensationofthepHsignalandnotforanyaccurate

andsafetemperatureindicationorcontroloftheprocess

temperature. If you anyhow want to try this, check that

your transmitter has the required temperature indication

accuracyandafree outletforthesignal.Furthermore,a

calibrationofthetemperaturesignalmightbenecessary.

en

InPro 3100 (i) pH electrode 17

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

6 Maintenance

1. Carefully rinse the electrode tip and diaphragm with

deionizedwateraftereachproductioncycle.Underno

circumstancesmustmeasuringsolutionbeallowedto

dryontheseparts!

2. When the electrode is not in operation, store it with

electrode tip and diaphragm well submerged into

9823 /3MKClor9816/Viscolyt™electrolyte.

3. Iftheelectrodeisstoredmounted initshousing,the

same rule as in 2) above applies, but the storage

electrolytehastobeslightlymodied,with2partsof

buffersolutionpH9.2to10partsofelectrolyte,thisin

ordertoavoidcorrosionofhousingparts.

4. Ifanelectrodeisstoreddryforafewdaysbymistake,

letitsoakinthenormalstorageelectrolyteforseveral

hoursbeforeuse.

5. Occasionallychecktheconnectorforpossibletracesof

moisture.Ifnecessary,cleanwellwithdeionizedwater

oralcohol,andafterwardsdrycarefully.

7 Trouble-shooting (sluggish response time,

insufcient sensitivity etc.)

TheglassmembranecanbereactivatedusingaHFsolution

(orderno.51319053).Theelectrodetip(onlypHsensitive

glasspart)isimmersedintotheHFsolutionforaperiodof

about5minutes,isthenimmediatelyandthoroughlyrinsed

withdeionizedwaterandthereafterstoredinbuffersolution

pH4(seepoint6above)uptothediaphragmfor12hours.

Po s sibleprot e inpre c ipitationandbl o c kag eofthedia p hr a gm

canbetreatedwithourspecialelectrodecleaner(orderno.

51340068).However,useofthediaphragmcleaner(order

no.51340070)isnormallynotnecessaryforthiselectrode

type,asthebuilt-insilver-iontrappreventstheformationof

silversuldecontamination.

Also,checktheconnectorforpossibletracesofmoisture.If

necessary,cleanwellusingdeionizedwateroralcohol,and

afterwardsdrycarefully.

8 Environmental protection

Wasteelectricalproductsshouldnotbedis-

posedofwithhouseholdwaste.Pleaserecycle

where facilities exist. Check with your Local

Authorityorretailerforrecyclingadvice.

9 Guarantee

Onmanufacturingdefects,12monthsafterdelivery.

en

18 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

1 Introducción ...................................................................19

2 Indicaciones de seguridad...............................................19

3 Descripción del producto.................................................19

4 Instalaciónypuestaenservicio ...................................... 20

5 Funcionamiento............................................................. 20

5.1 CalibracióndelelectrodoydeltransmisordepH ............. 20

5.2 Esterilización del electrodo ............................................. 20

5.3 SensordetemperaturadelInPro3100

(electrodo analógico) ......................................................21

6 Mantenimiento ...............................................................21

7 Subsanacióndeaverías(tiempoderespuestalento,

bajasensibilidad,etc.) ....................................................21

8 Eliminación ....................................................................21

9 Garantía ........................................................................21

Índice

es

InPro 3100 (i)

Electrodo de pH

Manual de instrucciones

InProeISMsonmarcasregistradas

del grupo METTLER TOLEDOenSuiza,EE.UU.,

laUniónEuropeayotroscincopaíses.

12 mm

0.47"

Tipodeconector(aquí:VP)

Electrolitointermedio

Barreracontraionesplataydiafragma

Electrolito de referencia

Sensordetemperatura

ElementodereferenciaArgenthal

Diafragma

VidriosensiblealpH

es Manual de instrucciones

InPro 3100 (i) pH electrode 19

© 08 / 22 METTLER TOLEDO InPro 3100 (i) pH electrode

Printed in Switzerland 52 002 293 B

1 Introducción

Los electrodos de pH tipo InPro™ 3100 (i) de

METTLER TOLEDO son electrodos de medida de

bajo mantenimiento, autoclavables y resistentes a

la presión, con electrolito de referencia gelicado. El

elemento de referencia incorpora el sistema silver-

ion trap (barrera contra iones plata), para evitar la

precipitación del sulfuro de plataen eldiafragma.Enel

casodelInPro3100,seintegraunsensordetemperatura,

queposibilitalacompensaciónautomáticadetemperatura

durantelacalibraciónymedidadepH.

Los electrodos InPro 3100(i) están especialmente

diseñados para medir el valor de pH en procesos de

biotecnología a presiones moderadas (<6bar). Pueden

utilizarseenfermentacionesindustriales,condicionespiloto

ydelaboratorio,yespecialmenteen procesosdondees

imprescindiblerealizarunaesterilizaciónintermediaotratar

en el autoclave.

Por favor, lea detalladamente estas instrucciones de

servicioantesdelapuestaenmarchaparagarantizarun

uso perfecto.

2 Indicaciones de seguridad

Los electrodos InPro 3100 (i) están diseñados sólo para

el uso que se describe en el apartado 1. El electrodo

tienepartesdevidrioydebemanipularseconcuidado.Si

selimpiaocalibra con disolucionesácidasoalcalinas,

se deben utilizar gafas y guantes de seguridad. La

manipulación del electrodo debe realizarse según las

regulaciones locales de seguridad. Para una instalación en

elámbitoEx,lerogamosconsiderelasdirectivasadjuntas.

Lerecomendamosqueutilicesolamenteelelectrodocon

piezas originales deMETTLERTOLEDO.Lamanipulación

y el servicio sólo deberían realizarse por personal y

trabajadores formados que hayan leído y entendido las

instrucciones de uso.

3 Descripción del producto

La impresión de cada electrodo contiene la siguiente

información:

METTLER TOLEDO Fabricantedelelectrodo

InPro™ 310X iUD / SG / yyy / zz Denominacióndeltipo;X=vidrio

demembrana;i=DigitalISM;

UD=instalaciónbocaabajo/

SG=electrodoauxiliar/

yyy=longituddelavarillaen

mm/zzz=tipodesondade

temperatura

combinationpH Tipo de electrodo

(CombinationpH)

pH0…14 GamademedidadepH

0…80°C/140°C(130°C) Rangodetemperaturadurante

elservicio/esterilización(para

InPro3100UD)

OrderNo.5200XXXX Númerodepedido

SEV14ATEX0168X Identicaciónynúmero

decerticado

IECExSEV14.0025X Identicaciónynúmero

decerticado

IS/I,II,III/1/ABCDEFG/T6 ComprobadosegúnFM

Seeinstructionmanual! Indicación(Tengaencuenta

las instrucciones de uso)

ParaobtenerinformaciónsobrelacerticaciónUKEX,

consultelaparteeninglésdeestemanual.

es

20 InPro 3100 (i) pH electrode

InPro 3100 (i) pH electrode © 08 / 22 METTLER TOLEDO

52 002 293 B Printed in Switzerland

Cadaelectrodose halla provisto ademásde un número

de serie en el cabezal enchufable, a n de permitir la

identicaciónytrazabilidad.

4 Instalación y puesta en servicio

1. Aldesembalar,compruebequeelelectrodonopresenta

dañosmecánicosenlamembranaoenelcuerpode

vidrio.Informeinmediatamentedecualquierdañoasu

proveedor METTLER TOLEDO.

2. Extraigaelcapuchónprotectorylaveelelectrodocon

agua desionizada. Tras el lavado, el electrodo debe

secarse ligeramente con papel suave. No frote la

membranadevidrio,yaqueellopuedegenerarcargas

electrostáticas y dar lugar a tiempos de respuesta

lentos.

3. Compruebe que no hay burbujas de aire en la

membranadevidrioy,dehaberlas,elimínelasagitando

elelectrodoligeramentecomosifuerauntermómetro

clínico.

4. Para la instalación del electrodo, vea el manual de

instrucciones de la sonda correspondiente.

5. Conecteelelectrodoal transmisordepH usandoun

cable con el conector apropiado (conector VP para

el InPro 3100). Rogamos consulte el esquema de

conexiónquesesuministraconelcable.

6. LoselectrodosinteligentescomoInPro310Xipermiten

elmétodo«PlugandMeasure»(enchufarymedir)yel

diagnósticoampliado.Paralainstalación,puestaen

servicioyfuncionamientodelsistemaISM® tenga en

cuentalasinstruccionesdeltransmisor,delmóduloy

del cable.

5 Funcionamiento

5.1 Calibración del electrodo y del transmisor de pH

Los electrodos InPro 3100 requieren una calibración en

dos puntos. Para calibrar, extraer primero el capuchón

protector.Paraacelerareltiempoderespuestadelelectrodo

despuésdeuntransporteoalmacenamientolargo,yantes

decalibrar,sumergirelelectrodoentampónpH7,tampón

pH 4 y de nuevo en tampón pH 7, durante un minuto

aproximadamente cada vez. El electrodo se sumerge

después sucesivamente en dos disoluciones tampón

diferentesconvaloresdepHconocidosyeltransmisorse

calibraalosvaloresdeestostampones.Normalmentese

empiezaconeltampónpH7paradeterminarelpunto0y

despuésseutilizaeltampónpH4ó9paradeterminarla

pendiente.Siseutilizantransmisoresconmicroprocesador

queyaincorporanelreconocimientodetampones,elorden

delosdostamponeselegidosesirrelevante.Siempreque

seaposible,sedebeconectarunsensordetemperaturaal

transmisor(enelcasodelInPro3100elquellevaintegrado),

yseleccionarlamediciónautomáticadetemperatura.Para

más detalles consultar el manual de instrucciones del

transmisor.

5.2 Esterilización del electrodo

Los electrodos InPro 3100 (i) pueden esterilizarse

mediante autoclave (extraiga el capuchón rojo) o

medianteesterilizacióninsituconvaporoconunmedio

de fermentación muy caliente. No se permite utilizar

temperaturasdeesterilizaciónporencimadelos140°C,

niunaexcesivaduracióndelaesterilización(porejemplot

>30mina140°C)quepodríaacortarconsiderablemente

la vida útil del electrodo. La repetida esterilización y/o

autoclave del electrodo puede provocar una ligera

coloracióndelelectrolito,aunqueestecambiodecolorno

afectaelfuncionamientodelelectrodo.

es

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

A página está carregando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

Mettler Toledo pH electrode InPro3100/InPro3100UD Instruções de operação

- Tipo

- Instruções de operação

em outras línguas

- español: Mettler Toledo pH electrode InPro3100/InPro3100UD Instrucciones de operación

- français: Mettler Toledo pH electrode InPro3100/InPro3100UD Mode d'emploi

- italiano: Mettler Toledo pH electrode InPro3100/InPro3100UD Istruzioni per l'uso

- English: Mettler Toledo pH electrode InPro3100/InPro3100UD Operating instructions

- русский: Mettler Toledo pH electrode InPro3100/InPro3100UD Инструкция по эксплуатации

- Nederlands: Mettler Toledo pH electrode InPro3100/InPro3100UD Handleiding

- Deutsch: Mettler Toledo pH electrode InPro3100/InPro3100UD Bedienungsanleitung

- dansk: Mettler Toledo pH electrode InPro3100/InPro3100UD Betjeningsvejledning

- čeština: Mettler Toledo pH electrode InPro3100/InPro3100UD Operativní instrukce

- svenska: Mettler Toledo pH electrode InPro3100/InPro3100UD Bruksanvisningar

- polski: Mettler Toledo pH electrode InPro3100/InPro3100UD Instrukcja obsługi

- 日本語: Mettler Toledo pH electrode InPro3100/InPro3100UD 取扱説明書

- suomi: Mettler Toledo pH electrode InPro3100/InPro3100UD Käyttö ohjeet